Custom-made Microfluidic Chips

Custom microfluidics chip fabrication

from prototype to mass production

Let us help you design your device

Introduction to Microchannel Technology

Contents

| ・Conpany Overview | ・PDMS Hydrophilization |

| ・PDMS Molding | ・Inspection and Measurement | ・Bonding of Dissimiller Materials | ・List of Achievements |

Custom-made Microfluidic Chip(Device)

We can offer prototyping and mass production of microfluidic chips (devices) with many years of experience in rubber product development. Our microfabrication technology enables us to design micro channels with complex shapes. We manufacture products under strict quality control in a clean environment (or booth), gaining high evaluation in the bio-research and medical fields in Japan.

What is "High-viscosity PDMS"?

PDMS is a type of silicone elastomer, commonly used as a material for microfluidic chips (devices). The high-viscosity PDMS we use has improved tensile and tear strength compared to regular PDMS, featureing high dimensional stability during molding.

Microfluidic Chip/Device Fabrication Examples

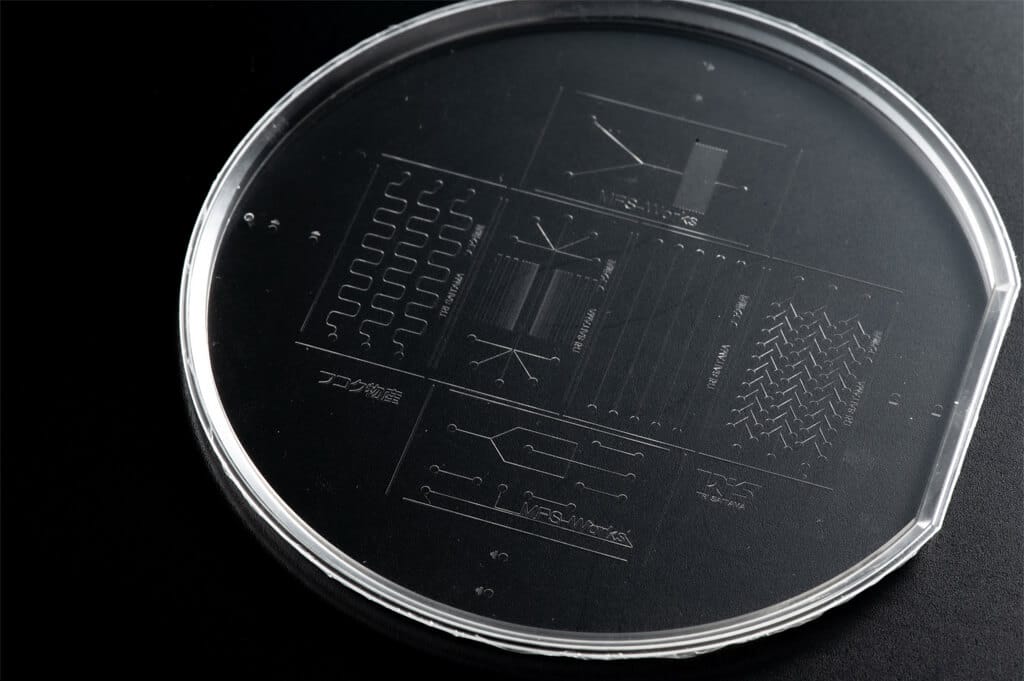

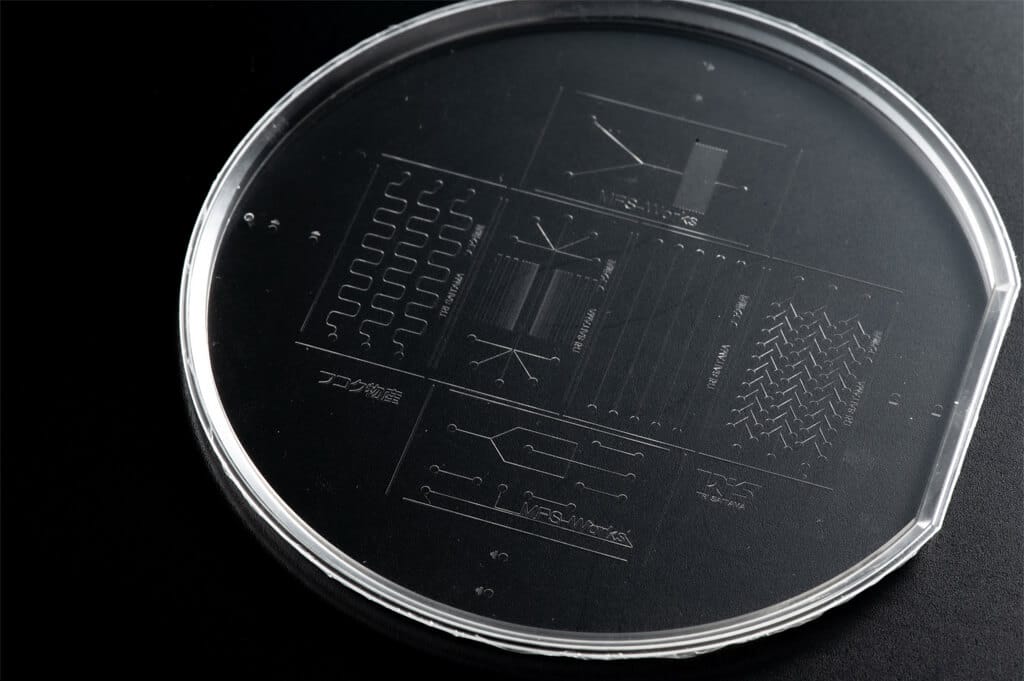

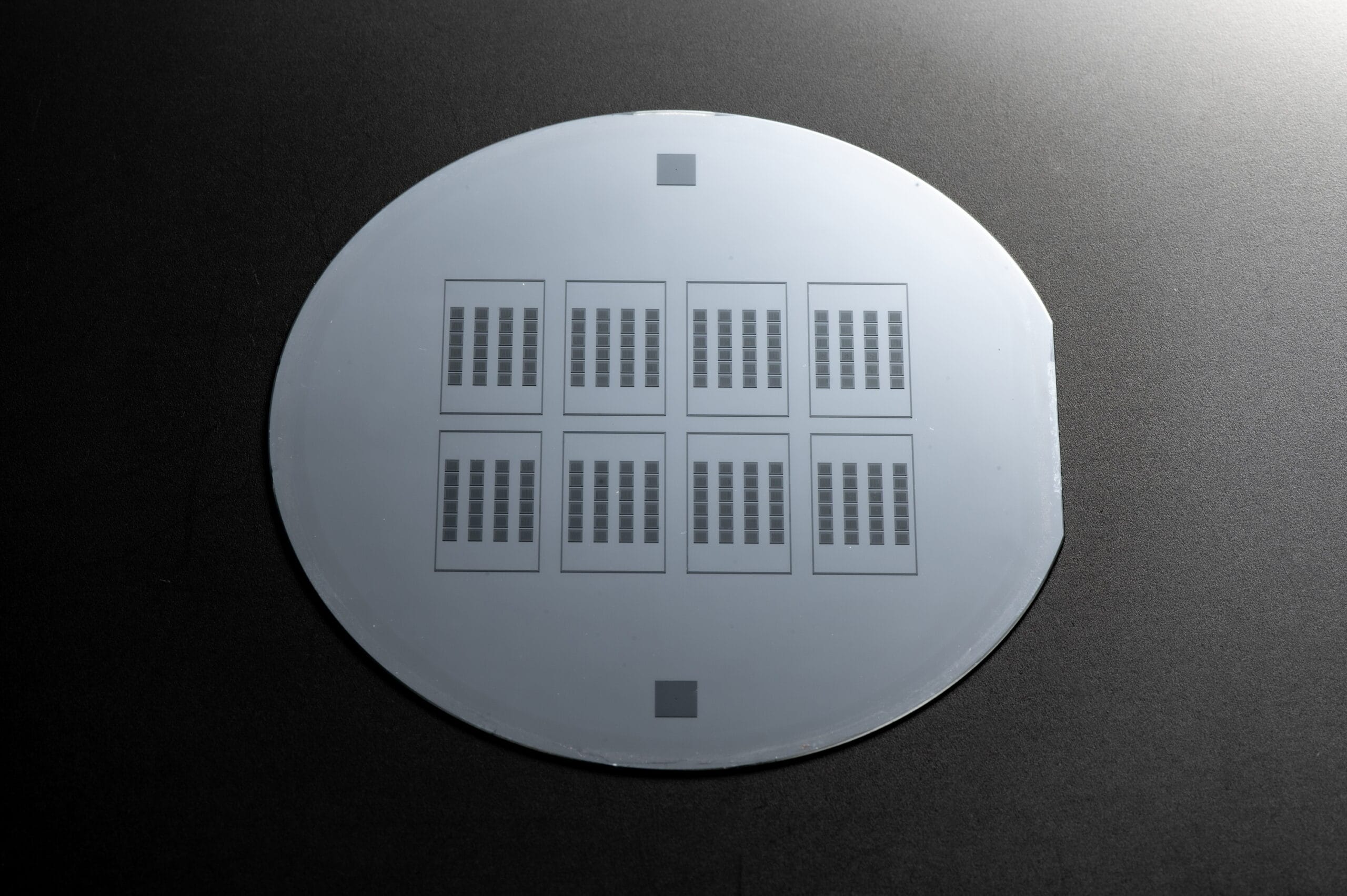

-

Microfluidic Chip

(made of PDMS)

- Material

- Highly transparent PDMS

- Size

- 4 inches

Flow channel depth: 50 µm

-

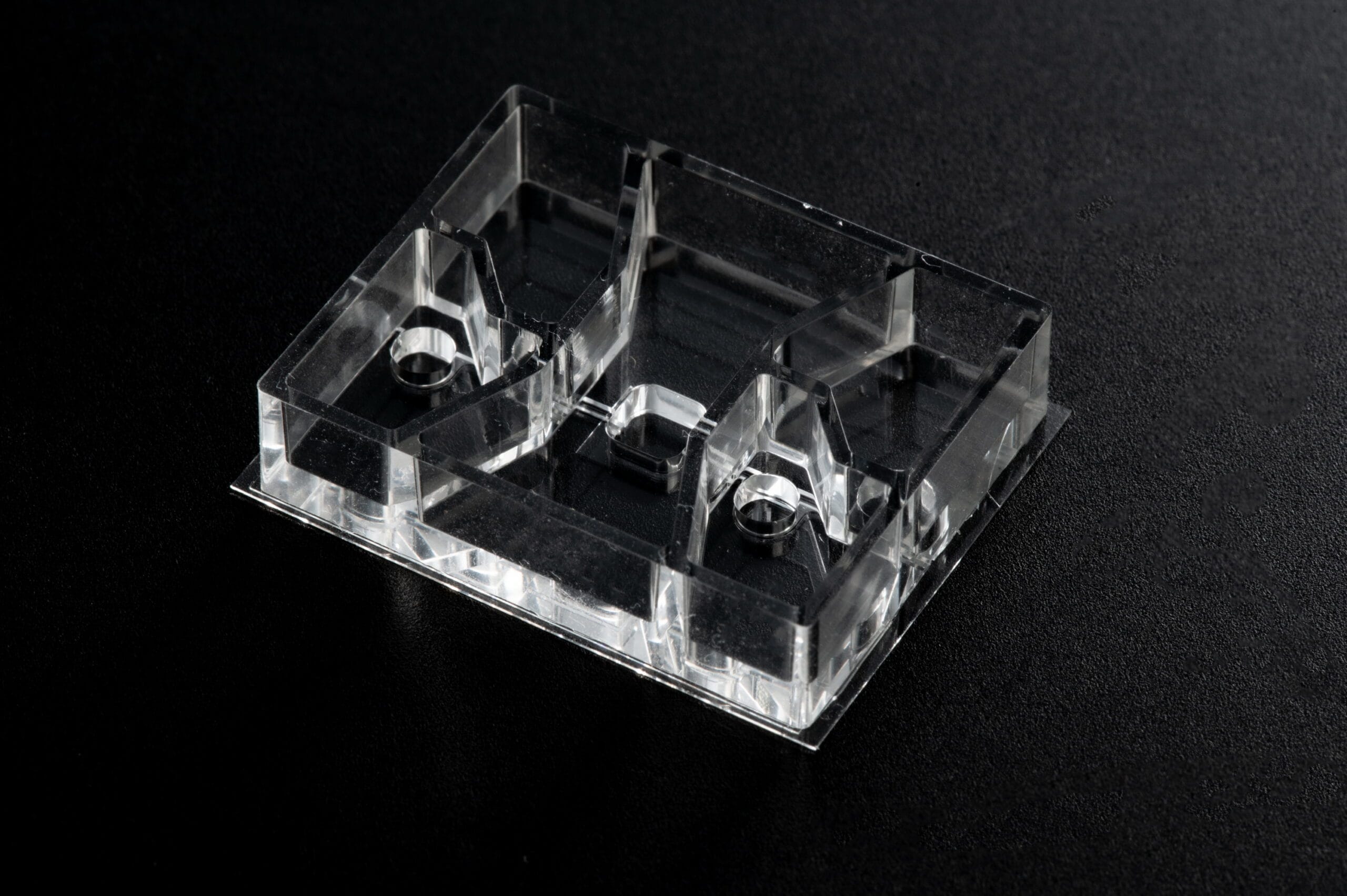

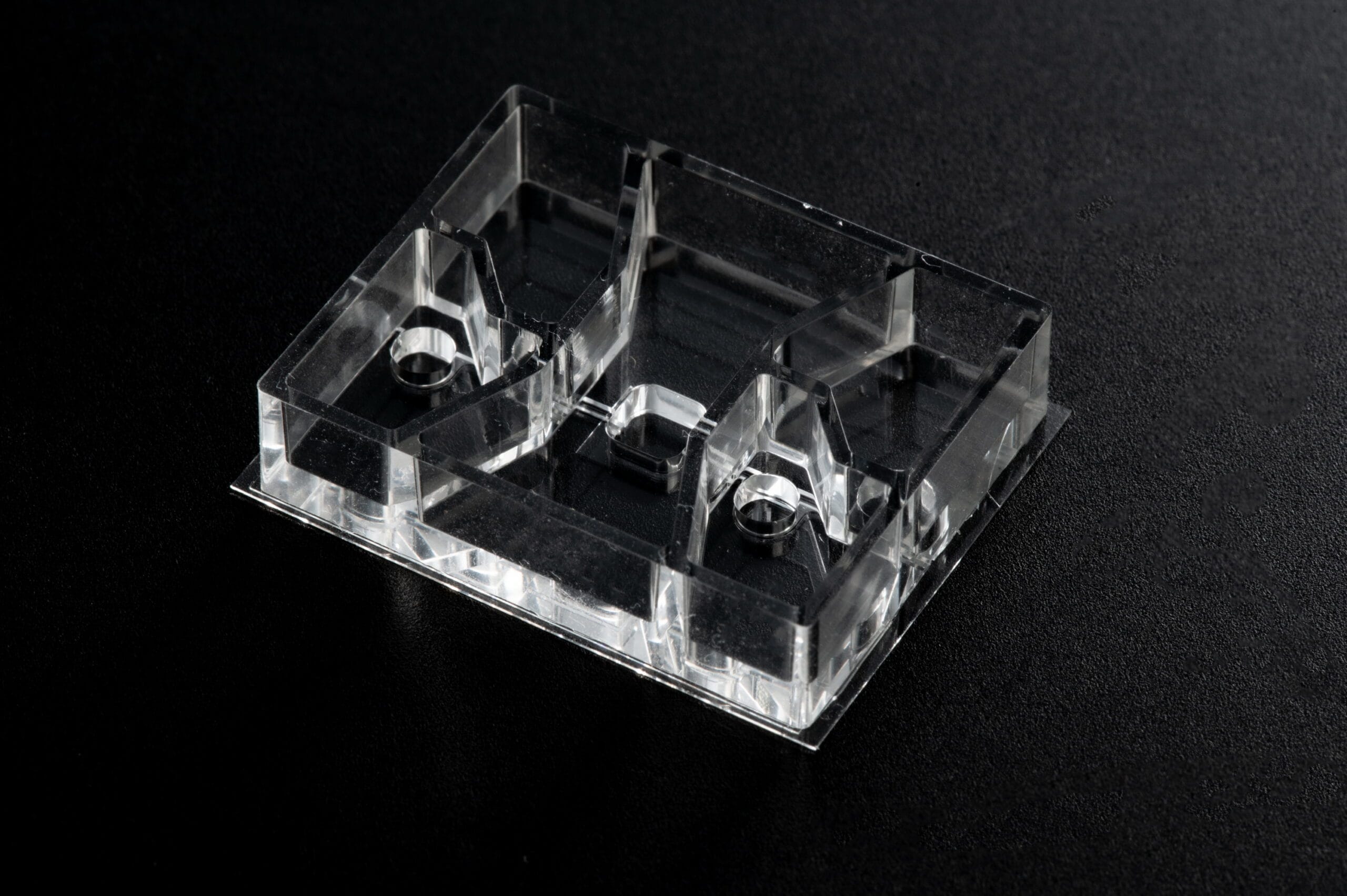

Microfluidic Chip

(made of PDMS)

- Material

- Highly transparent PDMS

- Size

- 50 x 45 x t1

Flow channel depth: 500µm

-

Microfluidic Chip

(Glass Bonding)

- Processing method

- PDMS molding + glass bonding

- Application

- Neuronal cell culture chip

-

Microfluidic Device

(Sheet + Glass Bonding)

- Processing method

- PDMS molding + sheet bonding + glass bonding

- Application

- Artificial blood vessel chip

-

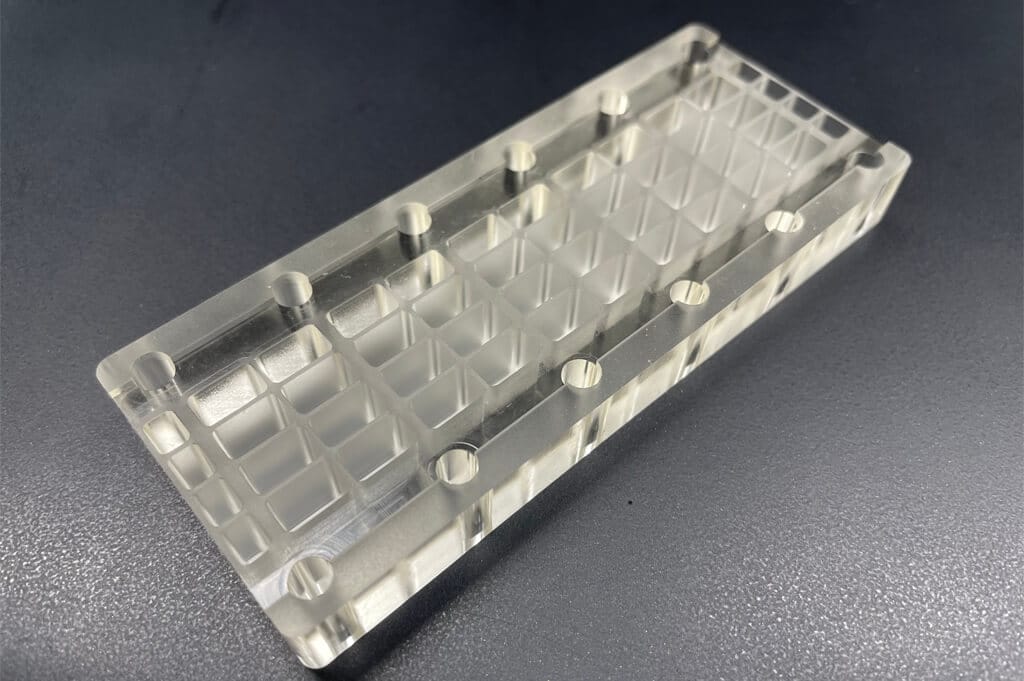

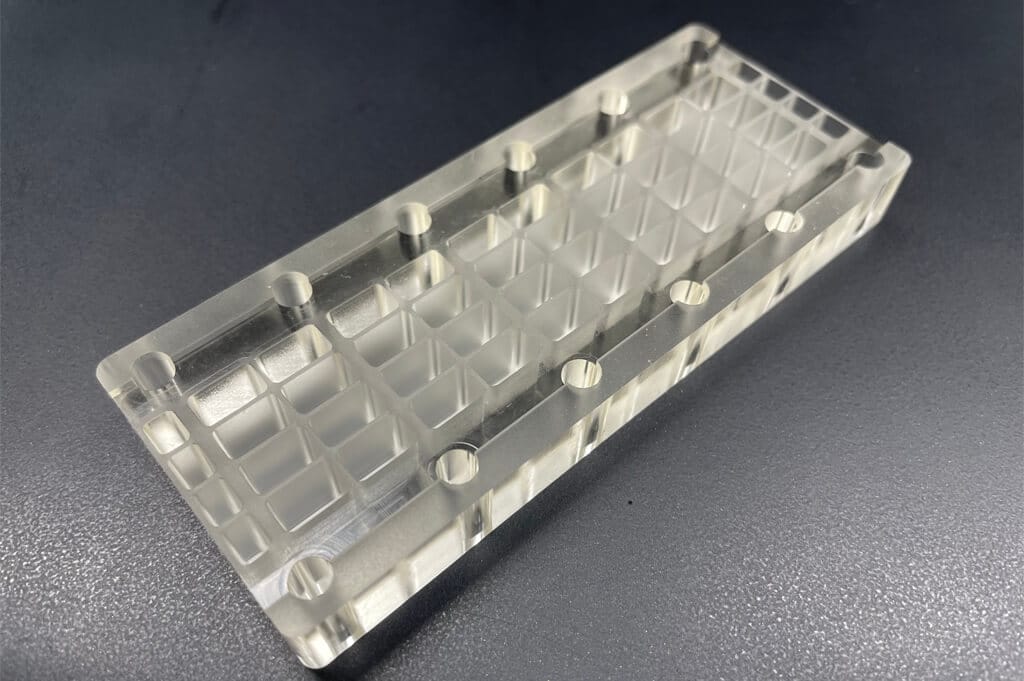

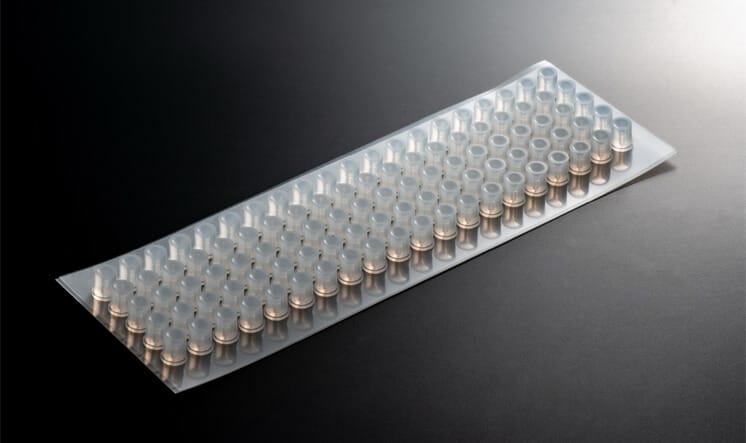

Microfluidic Device

- Processing method

- PDMS molding

- Application

- Multiwell stretch culture plates

-

Microfluidic Cassette

- Processing method

- PDMS molding + assembly + reagent injection

- Application

- Cassettes for E. coli measurement

Introduction to Microchannel Technology

Contents

| ・Conpany Overview | ・PDMS Hydrophilization |

| ・PDMS Molding | ・Inspection and Measurement | ・Bonding of Dissimiller Materials | ・List of Achievements |

Processing Range of Microfluidic Chip/Device

- Materials

- PDMS, High Viscosity PDMS

*We can also handle glass and resin (COP, PMMA, PS, PC, etc.). - Processing Method

- Transfer molding using resist and metal mold

- Size

- Resist mold: 4-inch wafer

Metal mold: up to 200 mm x 200 mm (7.87 inches x 7.87 inches) - Thickness

- 0.1 mm to 10 mm (0.0039 inches to 0.39 inches)

- Groove Depth

- Resist mold: 0.005 mm to 0.2 mm (0.0002 inches to 0.0079 inches)

Metal mold*: 0.1mm (0.0039 inches) and above *depending on the groove width - Groove Width

- Resist mold: 0.005 mm to 0.2 mm (0.0002 inches to 0.0079 inches)

Metal mold*: 0.1mm (0.0039 inches) and above *depending on the groove width

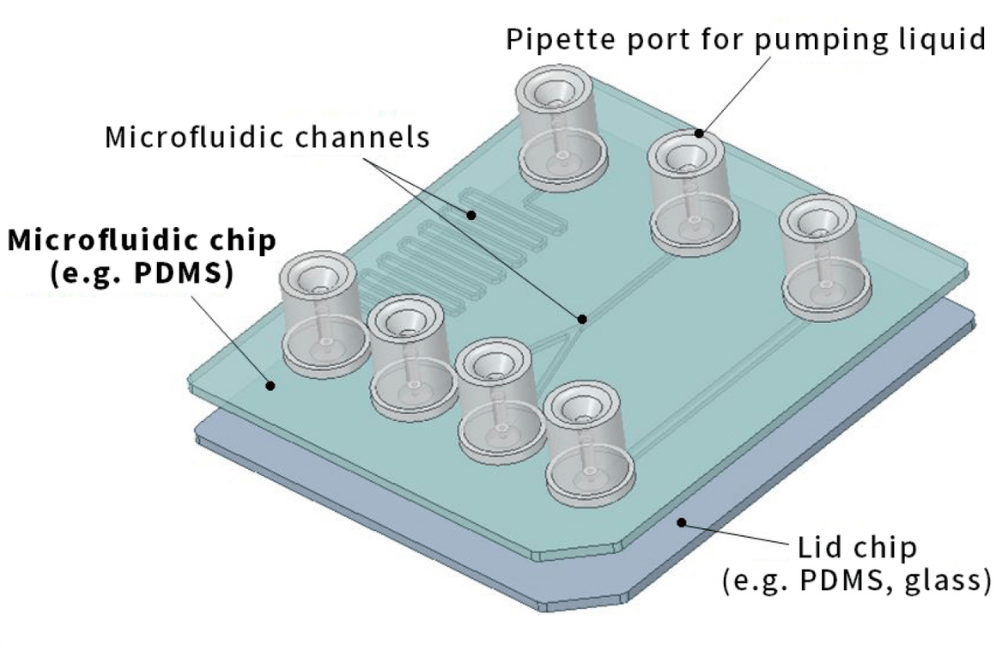

Pipette Ports for Liquid Transfer is Now On Sale!

By attaching Fukoku Bussan's original pipette ports to the inlet and outlet holes, you can securely connect pipette tips or liquid transfer tubes without leaks, ensuring that your valuable testing liquids are transferred without leakage.

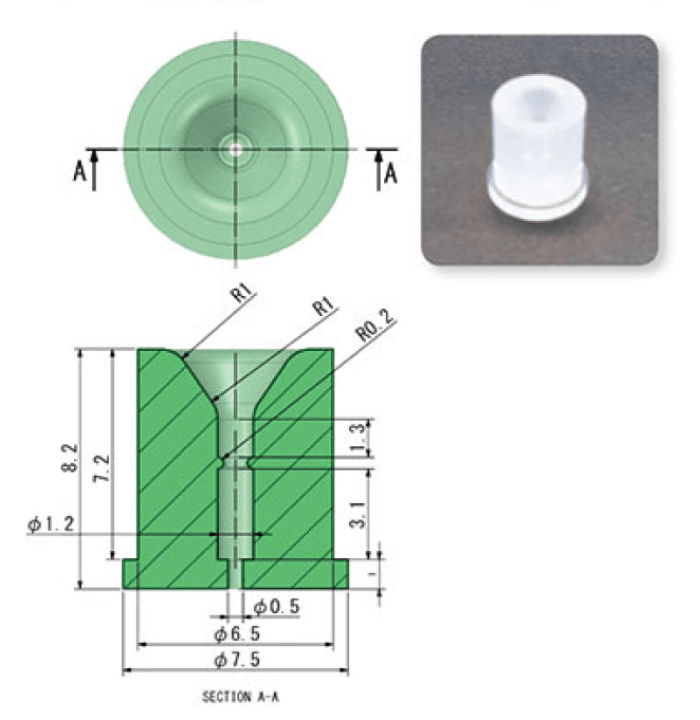

Pipette Port S

For pipette tips

(Yellow: 0.5 - 250 μL)

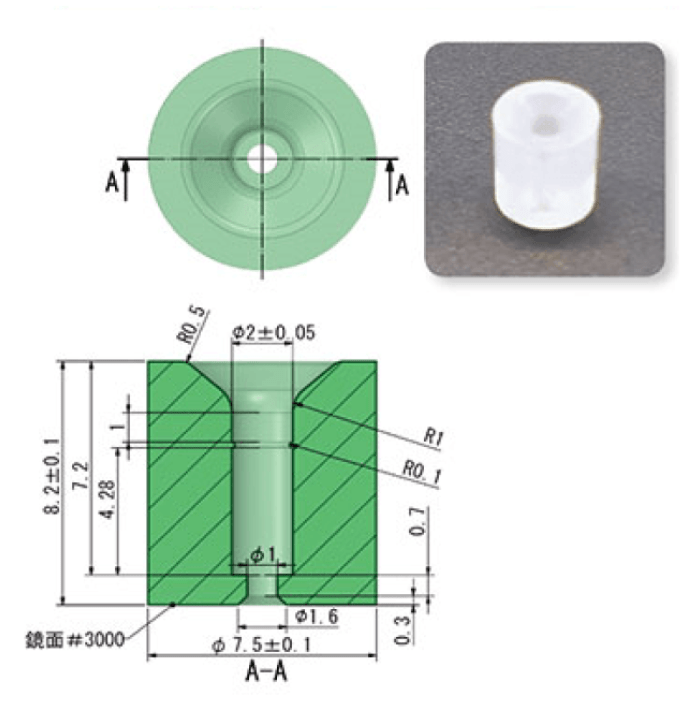

Pipette Port L

For tubes (Tube outer

diameter 2mm)

The port base is equipped with a silicone adhesive double-sided tape, ensuring a secure attachment to PDMS microfluidic channels. We also offer pipette ports without double-sided

tape.

Additionally, we provide plasma bonding services for bonding the ports to the microfluidic chips.

Feel free to contacts us if you are interested in any of these products!

Numerous pipette ports on a chip

Here's Why We're Special

-

1. PDMS Molding Technology

In our manufacturing of PDMS microfluidic chips, the core technology involves molding high-transparency PDMS using molds with fine channel structures formed by resist etching. This enables flexible production capabilities, ranging from small prototypes to a monthly production capacity of 1,000 units. Additionally, for smaller lot sizes, rapid prototyping with expedited casting is also available.

-

2. Biocompatible Bonding Technology

Our adhesive-free PDMS bonding uses plasma (atmospheric/vacuum) or excimer surface-modification to create strong, chemically stable, biologically inert bonds with glass, metal, and resins. Electron-beam and gamma-ray quantum-beam treatments further enable uniform, simultaneous multilayer bonding with assured biocompatibility.

-

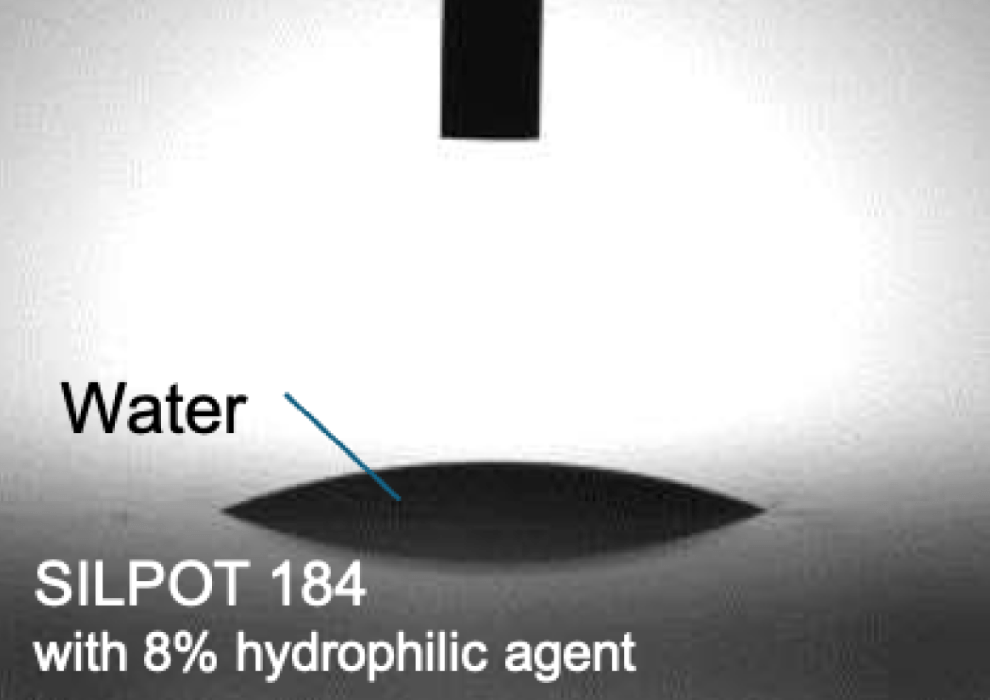

3. Hydrophilization Technology

By adding a hydrophilizing agent to PDMS during the molding process, the material's surface is modified to become hydrophilic. This process significantly improves the flow rate when introducing liquids into the microfluidic channels while retaining the inherent properties of PDMS. Additionally, by adjusting the amount of additive, the water contact angle can be optimized, ensuring that the hydrophilicity is maintained over long-term use.

-

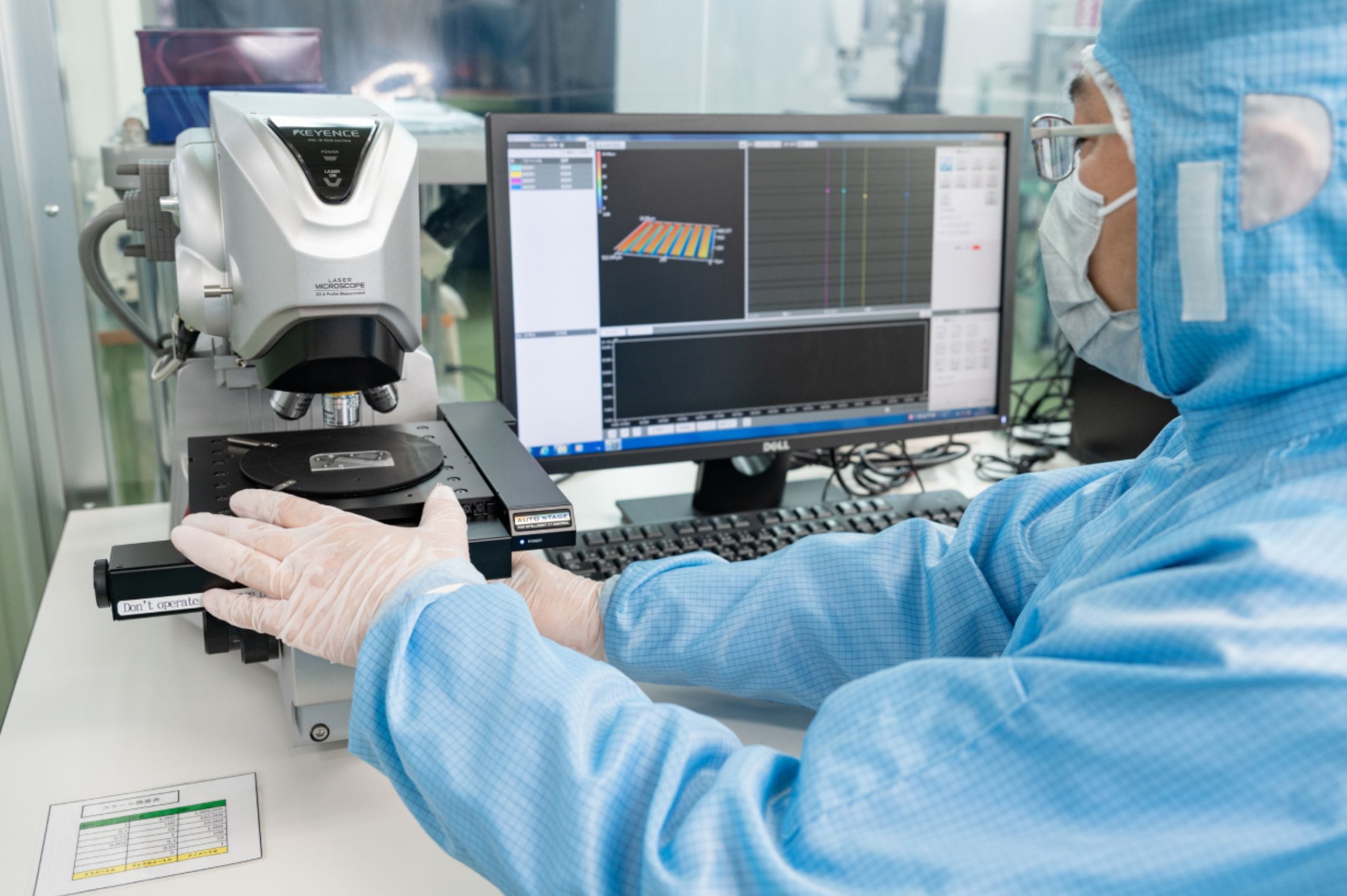

4. Inspection Technology

The quality of microfluidic chips is rigorously inspected in a clean environment. We use specialized inspection equipments suited to the purpose, including microscopes, electron microscopes, laser microscopes, and 3D shape measurement devices, to verify the precision within the channels. This ensures the precision and quality of the products.

Flow of Microfluidic Chip/Device Fabrication

-

01Mold Design and Production

Design and produce molds for creating microfluidic channels. Depending on the number of microfluidic chips (devices) to be produced, consider whether to create a prototype mold or a mold for mass production.

-

02Molding and Secondary Processing

Low-viscosity PDMS is poured into the fabricated mold, and molding is completed by allowing it to solidify over time. Additionally, perform any necessary secondary processing required for usage.

-

03Inspection, Packaging, & Shipping

Conduct inspections and operation checks, then package and ship the products. Our company aims for zero complaints through thorough quality control in a clean booth environment.

About us

Fukoku Bussan's SD Development Center focuses on the manufacturing and sales of microfluidic chips, accommodating various materials such as PDMS, COP, and PMMA. It offers flexibility to meet needs from single prototypes to mass production, providing comprehensive development support utilizing its trading company functions. Additionally, it offers extensive measurement, inspection, and observation services.

Contact Us

TEL: +81-3-3765-3233 (Monday to Friday, 9:00 AM to 5:30 PM JST)

Frequently Asked Questions

-

Q1: Can you handle small batches at the prototype stage?

We can handle prototypes starting from a single piece. Please consult with us first. Once your project progresses, we will provide a quote for your desired batch size.

-

Q2: Can you handle the design if I don't have shape data?

If you provide rough sketches or approximate dimensions, we can handle the design. We will proceed with prototyping after confirming the design with you.

-

Q3: Can you handle small batches at the prototype stage?

We can handle prototypes starting from a single piece. Please consult with us first. Once your project progresses, we will provide a quote for your desired batch size.

-

Q4: Can you sign a non-disclosure agreement (NDA)?

Yes, we can. Most of our customers in this industry have NDAs, so you can rest assured.

-

Q5: Do you support processing in a clean room?

We work in a "clean booth" (not in a clean room). Although it is set to Class 10,000, it operates at an effective Class 1,000 level. For stricter quality requirements, we also have a Class 100 clean bench.

-

Q6: What information is needed to request a quote?

We can provide a quote if you provide information on the material, product shape (external dimensions, channels, etc.), application, and batch size.

-

Q7: Can you handle small batches at the prototype stage?

We can handle prototypes starting from a single piece. Please consult with us first. Once your project progresses, we will provide a quote for your desired batch size.

-

Q8: Do you handle materials other than PDMS for microfluidic chip fabrication?

Yes, we can handle hard resins such as PMMA, COP, and PC, among others. We also deal with films, so please consult with us!

-

Q9: Can you handle bonding of different materials?

Yes, we can. Although bonding may be impossible with some materials, we will consider various equipment options. If you provide the materials in advance, we can also perform bonding trials, so please feel free to consult with us.

-

Q10: What types of PDMS hardness can you handle?

Molding and assembly generally take about 1 to 2 weeks (if mold production is required, it will take additional time based on the specifications). The time required depends on the shape and complexity, but we will do our best to meet your needs.

-

Q11: How long does it take for processing?

Molding and assembly generally take about 1 to 2 weeks (if mold production is required, it will take additional time based on the specifications). The time required depends on the shape and complexity, but we will do our best to meet your needs.

-

Q12: Can you provide various suggestions for manufacturing?

Yes. With many years of experience in rubber manufacturing and secondary processing know-how, we can make suggestions tailored to your specifications. We can also propose material or shape changes for cost reduction.

-

Q13: Do you ensure proper quality assurance?

Yes, we can conduct detailed quality inspections based on your inspection standards and specifications. We can also handle 100% inspections using microscopes upon request. We ensure material and production lot management and provide reliable traceability, so you can rest assured.